3D printing in space is changing how we explore. It cuts costs, boosts efficiency, and makes long missions easier. 3D printing is changing space travel. It helps make spacecraft parts and build habitats on Mars. NASA, SpaceX, and other agencies are putting a lot of money into 3D printing tests. They want to explore how additive manufacturing can work beyond Earth. But how exactly is this technology reshaping the future of space exploration?

The Role of 3D Printing in Space Exploration

Reducing Dependence on Earth-Based Supply Chains

A major challenge in space missions is the high cost and complexity of moving materials from Earth. 3D printing in space lets astronauts make important tools, spare parts, and structural pieces. This means they don’t need to depend on expensive rocket launches. This capability:

- Minimizes supply chain delays and costs.

- Increases mission flexibility by enabling on-demand production.

- Reduces payload weight, allowing spacecraft to carry more essential supplies.

NASA has estimated that launching a single kilogram of payload into space can cost upwards of $10,000. Using NASA’s 3D printing experiments, agencies can significantly reduce costs. This makes space missions more sustainable over time.

NASA’s 3D Printing Experiments and Developments

NASA leads in 3D printing in space. They partner with private companies to test new manufacturing solutions. Some key projects include:

- Made In Space’s 3D printer: It can print tools and parts in microgravity. This proved that 3D printing can work in low-gravity environments and is viable for deep-space missions.

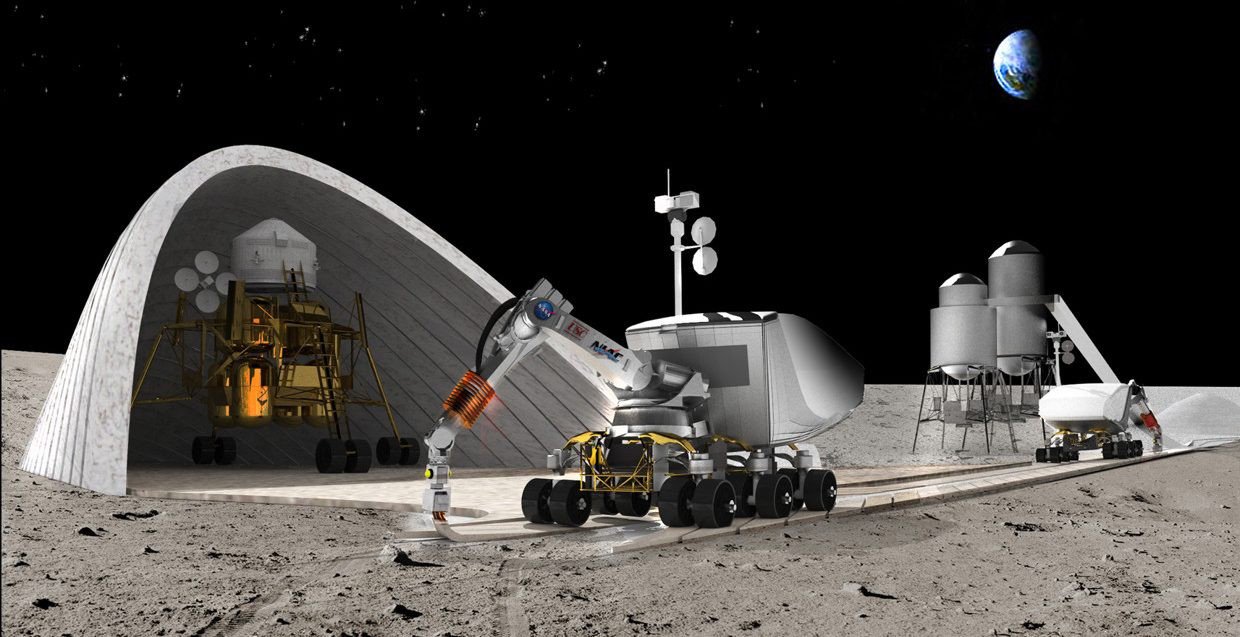

- NASA’s Artemis program: Investigating 3D-printed habitats for sustainable lunar colonization. Future lunar bases might use 3D-printed structures made from Moon dust. This would cut down the need to bring materials from Earth.

- Regolith-based printing: Tests use Moon and Mars soil to make building materials for future space habitats. Researchers believe this could lead to self-sustaining colonies on other planets.

SpaceX and Private Industry Contributions

Beyond NASA, private companies like SpaceX and Blue Origin are leveraging 3D printing for:

- Rocket engine production: SpaceX’s SuperDraco thrusters and Blue Origin’s BE-4 engines use 3D-printed parts. This cuts costs and speeds up manufacturing. Additive manufacturing lets these companies make complex engine parts much faster than traditional methods.

- Satellite construction: 3D printing makes lightweight and efficient satellite structures. This boosts performance and cuts production costs. Relativity Space is developing fully 3D-printed rockets. One example is the Terran 1. This rocket aims to change how we launch into space.

Building Habitats on Mars with 3D Printing

The Challenge of Martian Colonization

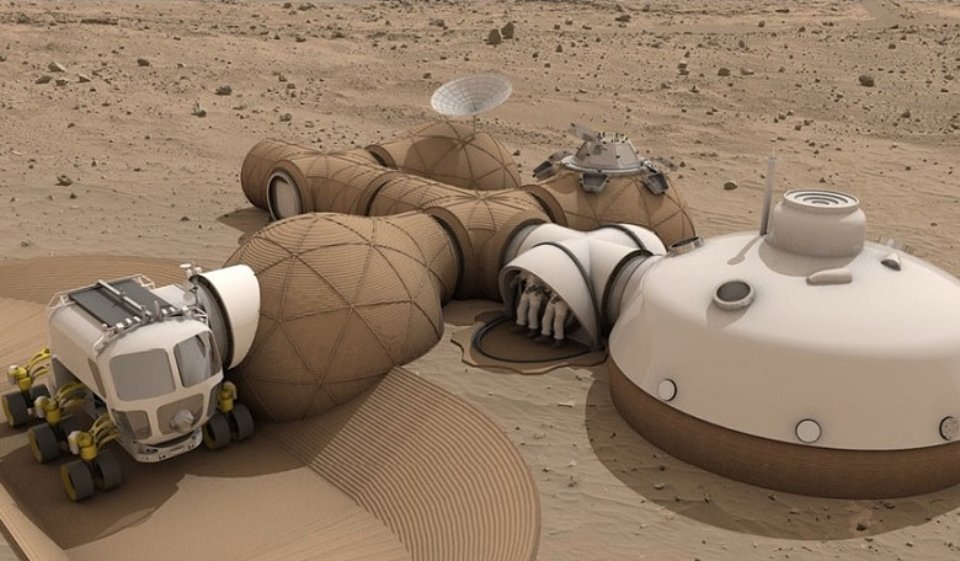

To have a lasting presence on Mars, we need strong, self-sufficient buildings. They must handle extreme conditions. Building habitats on Mars with 3D printing provides a viable solution by utilizing local materials and automated construction. Mars has a tough environment. It has high radiation, big temperature changes, and dust storms. So, traditional construction methods just won’t work.

Mars Habitat Prototypes

NASA’s 3D-Printed Habitat Challenge has encouraged innovative designs for future Martian settlements. Leading concepts include:

- AI SpaceFactory’s MARSHA: A 3D-printed, egg-shaped habitat designed for maximum structural integrity. Its vertical design helps withstand Mars’ pressure differentials and provides natural insulation.

- ICON’s Project Olympus: Developing lunar and Martian habitats using automated 3D printing systems. ICON has already printed Earth-based prototypes that demonstrate the viability of off-world construction.

- Contour Crafting: A large-scale construction technique that prints entire buildings layer by layer using Martian regolith. This technology could be deployed by autonomous robots before human arrival.

Benefits of 3D-Printed Mars Habitats

- Resource efficiency: Utilizes Martian soil, eliminating the need to transport building materials.

- Autonomous construction: Robotic printers can build habitats before human arrival, reducing the risks to astronauts.

- Radiation protection: Thick, 3D-printed walls made from regolith can shield astronauts from cosmic radiation, which poses a significant threat to long-term missions.

- Scalability: As printing technology advances, entire colonies could be built using local materials, allowing Mars settlements to expand organically.

Quick Guide: 3D Printing in Space—Key Highlights

- 🛠 In-Space Manufacturing: Astronauts can print tools and spare parts on-demand, reducing reliance on Earth.

- 🧱 Martian Habitats: NASA and ICON are testing regolith-based 3D-printed buildings for Mars and Moon colonies.

- 🚀 Rocket Parts & Satellites: Companies like SpaceX use 3D printing to build lightweight, cost-efficient engines and components.

- 🧬 Bioprinting Organs: Space-based bioprinting may help astronauts survive long missions with in-space medical care.

- ♻️ Sustainable Exploration: Future plans include recycling space debris into raw materials for 3D printers.

Pro Tip

Want to follow the cutting edge of 3D printing in space? Watch NASA’s Artemis program and companies like ICON and Relativity Space for the latest breakthroughs in off-world construction and manufacturing.

Important

3D printing in space isn’t just about convenience—it’s essential for survival. Long-term missions to Mars or deep space will require astronauts to manufacture tools, food systems, and even medical supplies autonomously. Learning how to 3D print in microgravity is a critical step for humanity’s expansion beyond Earth.

The Future of 3D Printing in Space

Printing Human Organs for Space Medicine

Astronauts on long-duration missions face significant medical risks. Researchers are exploring bioprinting technologies to produce human tissue and potentially organs in space, offering:

- On-site medical solutions for emergencies, reducing dependence on Earth-based medical support.

- Reduced reliance on organ donors by growing replacement tissues.

- Accelerated tissue growth in microgravity, as some studies suggest that the lack of gravity helps cells grow in three dimensions more effectively than on Earth.

NASA and private firms are testing the feasibility of bioprinting functional organs in space, which could lead to groundbreaking medical advancements for both astronauts and Earth-based patients.

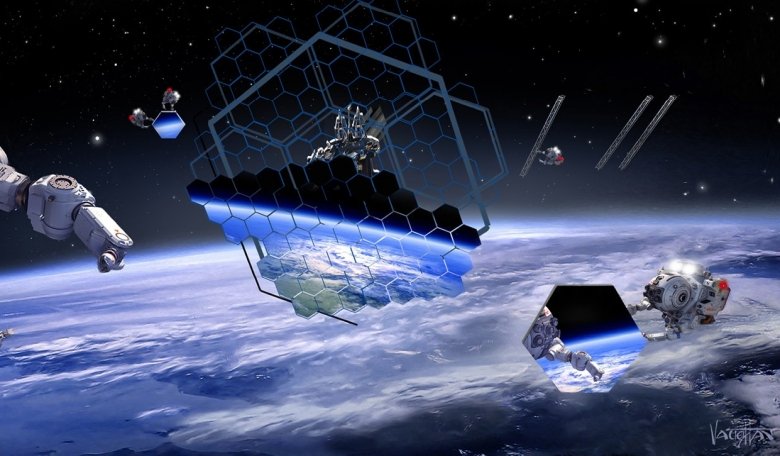

Manufacturing Entire Spacecraft in Orbit

In the long term, advancements in 3D printing in space could lead to in-orbit manufacturing of entire spacecraft and satellites. Potential benefits include:

- Eliminating launch constraints: Structures could be built in space rather than transported from Earth, removing the limitations imposed by rocket payload capacities.

- Modular spacecraft designs: Components can be printed and assembled on demand, enabling rapid adaptations to mission needs.

- Recycling space debris: Future 3D printers may repurpose defunct satellites as raw material, reducing orbital clutter and promoting sustainable space exploration.

Lunar and Martian Agriculture with 3D-Printed Tools

To sustain long-term space missions, astronauts will need to grow food in space. 3D printing in space could enable the creation of customized farming tools, hydroponic systems, and even soil-enrichment solutions. By leveraging 3D printing, future space farms could:

- Reduce reliance on Earth-based food supplies.

- Enhance sustainability through resource-efficient agricultural systems.

- Support long-duration missions by creating self-sufficient colonies.

Top 5 FAQs: 3D Printing and Space Travel

1. Why is 3D printing important for space missions?

It allows astronauts to create tools, parts, and even habitats on-demand, reducing costs and reliance on Earth-based resupply missions.

2. Can you really print buildings on Mars?

Yes—NASA and partners have developed techniques using Martian regolith (soil) to 3D-print structures, potentially enabling future habitats for astronauts.

3. What companies are leading in space 3D printing?

NASA, SpaceX, Blue Origin, Relativity Space, and Made In Space are at the forefront of additive manufacturing for space applications.

4. Is 3D bioprinting in space actually possible?

Yes. Researchers are exploring the potential to print human tissue and organs in microgravity, which could revolutionize space medicine.

5. Could spacecraft be built in space using 3D printing?

In the future, yes. The goal is to manufacture and assemble satellites or spacecraft in orbit, avoiding the limitations of Earth-based launches.

3D Printing – The Blueprint for Humanity’s Future in Space

The integration of 3D printing in space is set to revolutionize space travel by enhancing efficiency, reducing costs, and enabling sustainable human settlements beyond Earth. From NASA 3D printing experiments on the ISS to the potential of building habitats on Mars, this technology is paving the way for a new era of space exploration. As research continues to advance, 3D printing could become the backbone of deep-space missions, making once-impossible ideas a reality.

The implications of 3D printing extend beyond the confines of our planet. As private companies and space agencies refine their techniques, we may soon witness a future where interplanetary construction, on-demand manufacturing, and even organ printing become the norm. The question now is not whether 3D printing in space will change space travel, but how quickly it will redefine the future of humanity’s journey beyond Earth.

What are your thoughts on 3D printing’s role in space travel? Let us know in the comments!